Kutes Machine

Established in 2017 under Kutes, one of the leading companies of its sector, Kutes Makine invests and operates in line with the targets of the Turkish industry sector to grow and catch up with the world standards.

Who are we?

Kutes Makine has the potential and capacity to realize high-volume and high-tonnage processing projects while coming out with its production methods and processes in accordance with universal quality norms.

Efficient Production Processes with Kutes Makine

Supporting production activities in many different sectors, Kutes Makine is involved in production projects from the proposal stage to the mass production process. Kutes Makine has ISO 16949 certificate and ensures that its production processes are valid all around the world thanks to its broad vision and high-quality standard. Going into action to increase the total quality and efficiency of the production process, Kutes Makine enriches the production activities of all the companies it works with by offering innovative solution suggestions and modern production techniques to its partners.

Thanks to its CNC-CMM capacity Kutes Makine offers its partners the opportunity to benefit from the latest technology and fully support their design, engineering, production and quality control stages. Kutes Makine has all capabilities to meet your company's needs such as marking, assembly, washing, honing, lapping, broaching with the highest quality and it offers you a great advantage by ensuring that all of your production operations are managed from a single center. Meeting your production needs from a single source reduces your logistics and process management costs and increases the quality of products.

Kutes Makine has 14 different processing tools, its annual production time is 100,000 hours and the company is able to assemble 80,000 parts per year thanks to its expert engineers and experienced technical team. Kutes Makine produces 70% iron and 30% non-ferrous materials; it can process all steel, iron and composite materials in a quality that complies with the world standards.

Machine and Control Quality leads to "Zero Defects"

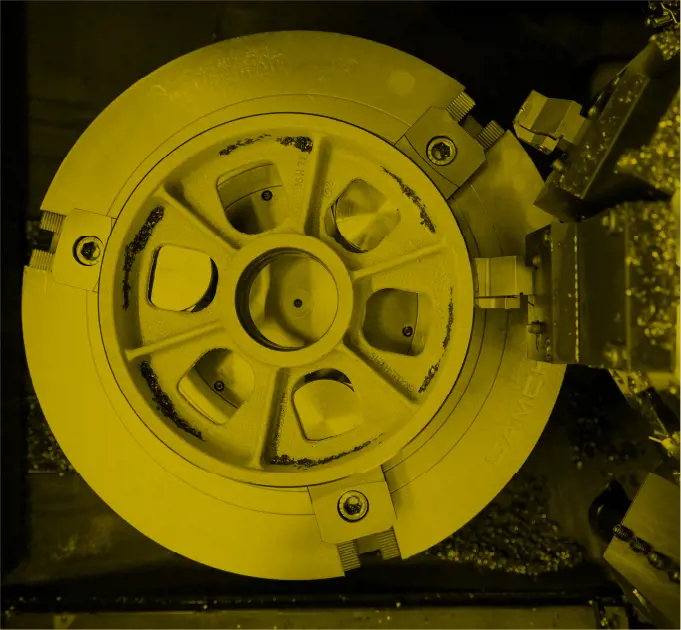

Kutes Makine operates more than 58,000 hours per year with 5 DMG Mori and 4 Doosan marking machines. Kutes Makine, which carries out all of its operational processes with the "Zero Defects" policy, also increases its control power with the quality control processes carried out after the production. Performing quality control with CMMs produced by brands such as Zeiss, COORD, and MAHR, Kutes Makine can detect and eliminate errors even in a millionth of a centimeter. The benches and machines used by Kutes Makine are as follows:

Doosan DNM5700 vertical machining center, size: 1300x570 mm, capacity: 1000 kg,

Doosan V8300 vertical turning center, height: 780 mm,

Doosan V8300M vertical turning center with drilling and milling options, height: 780 mm,

Doosan GT2100MB horizontal turning center with drilling option, height: 500 mm,

2 DMG Mori NHX5500 horizontal machining centers, height: 1100 mm, weight 1000 kg,

2 DMG Mori NHX6300 horizontal machining centers, height: 1300 mm, weight 1500 kg,

NZX 2000 / 800 horizontal turning center with drilling and milling options,

Zeiss Contura 3D measuring machine,

Zeiss Prismo 3D measuring machine,

COORD 3 3D measuring machine,

MAHR PS 10 surface roughness tester.

Sustainable Vision and Strong Mission

Kutes Makine has an environmentally friendly production approach with its vision of sustainability, and in this direction, it carries out its production with an approach that will reduce the carbon footprints of the Company and its partners. Solar panels with a capacity of 240kWh located on the roof of the factory facilitate the emphasis on green energy in production and prevent high-volume industrial production from harming the environment.

Kutes Makine, which protects the health of its employees as well as the nature and offers a hygienic working environment in all operational areas, enables your company to benefit from the same advantages as its competitors all around the world in the field of production thanks to its strong mission. Kutes Makine, which performs inventory and edge control perfectly with its tool management systems and automatic tool cabinets, contributes you to catch up with universal manufacturing norms with its innovative approach.